Process-Tech

Laminated steel, Anti-fingerprint coating, Roll-to-Roll production, slitting

Lienchy Metal utilizes a continuous production line to manufacture laminated steel, anti-fingerprint stainless steel (AFP), and pre-coated metals, ensuring efficient and consistent product quality. The production line is designed by Japan’s leading equipment manufacturers, including Sumitomo Heavy Industries and Honda Metal, and installed and tested by 大洋製鋼, meeting world-class technical and equipment standards.

To enhance product quality, Lienchy Metal's laboratory operates under the technical guidance of Japan’s Riken Corporation and conducts quality inspections according to JIS K6744 testing standards to meet stringent performance requirements. The company is ISO 9001 certified, with a production line spanning 350 meters and an annual capacity exceeding 50,000 tons, ensuring a stable supply to global markets for applications in construction, industrial, and home appliance sectors.

We offer a wide range of film colors and designs, as well as a variety of different surface coating treatments.

For laminated steel products, using cold-rolled steel sheets, hot-dip galvanized steel sheets, electrogalvanized steel, stainless steel, and aluminum as substrates. The substrate thickness ranges from 0.3 to 1.60 mm. The maximum width is 1300 mm.

Specification of Laminated metal Product

| Item | Width | Length | Torrlence | Inside Diameter |

|---|---|---|---|---|

| Sheet | 200-1250 mm | 300mm - 3,048mm | ±1 mm | -- |

| Coil | 58-1250 mm | Any Spec. | ±0.5 mm | 508 mm |

| Item | Type | Thickness | Tolerence | |

| Base Metal | CR, SECC, SGCC, AL, AL/MG, SU, Other metal | 0.286-1.6 mm | According to JIS | |

| Surface Layer | PVC,PET+PVC,PP,PVC+PP,PVF | 0.05-0.25 mm | ±0.04 mm | |

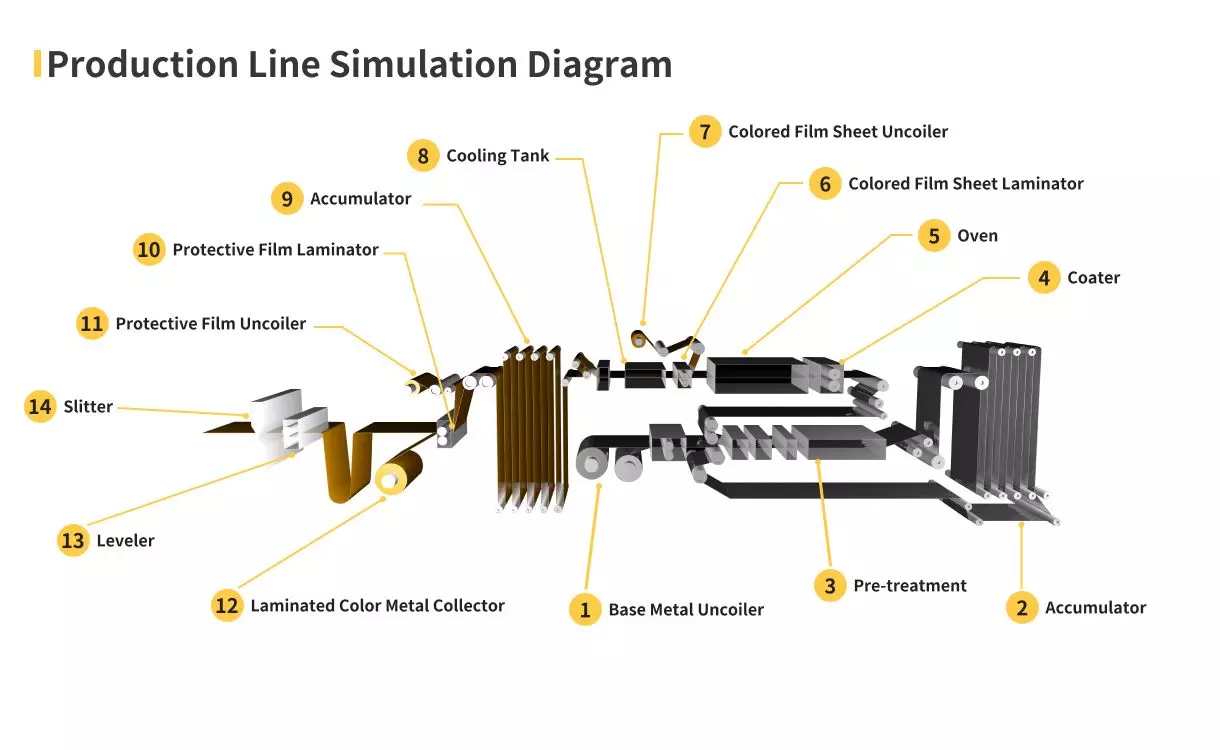

Lien Chy Metal Roll to Roll Coating Line

Production Line Introduction

Lienchy Metal's high-quality laminated metal products come from our high-precision roll-to-roll production line and the professional operation of our staff. The above picture is a schematic diagram of the roll-to-roll production line, from steel coil feeding to laminating film, to Collecting and Cutting, every stage of our production process is strictly checked. The following paragraph is a detailed introduction of the production process:

- Base Metal Uncoiler - Input steel coil to the production line

- Accumulator - Continuously production, when it comes to replace the raw material, there's a

buffer for on-site staff to proceed the replacement

- Pre-treatment - Cleaning the materials' surface

- Coater - Roller coating adhesive layer and AFP (anti-fingerprint) layer

- Oven - Heat up the steel with oven, in order to chemicalize the adhesive and

AFP (anti-fingerprint) layer

- Colored Film Sheet Laminator - After adhesive layer is chemiclized, start laminating

with steel surface

- Colored Film Sheet Uncoiler - Input color filing (roll) to the production

line

- Cooling Tank - Put laminated and AFP coating finished products into the tank to cool

down the temperature of substrate

- Accumulator - Continuously production, when it comes to replace the raw material, there's a

buffer for on-site staff to proceed the replacement

- Protective Film Laminator - After cooling down, laminating the processed surface with

protective film, to avoid the surface damage

- Protective Film Uncoiler - Input protective film (roll) to the production

line

- Laminated Color Metal Coil Collector - Through the whole process, after heating and

cooling collect in coil, that's roll-to-roll coating production

- Leveler - Flating the surface of substrate, to decrease the curve rate of

surface

- Slitter - Coil cuts into sheets (length)

During the production process, we perform manual inspections and AOI inspections, such as color and adhesion, to

ensure compliance with ISO standard. The continuous producing technology of Lien Chy Metal can ensure high

quality products. Lien Chy has excellent machinability and excellent durability to withstand subsequent bending,

stamping and other post-processings.

We have a wealth of experience and engineering design flexibility to adapt to the individual needs of our customers. These may involve technical specifications, the quality of the substrate, mechanical properties, film properties, special color and design requirements, and processing requirements. These parameters are produced after a thorough discussion with customers and a large number of laboratory experiments and pilot runs. We have a strict factory management and process planning to ensure high quality products and timely and accurate delivery.

- Film about Cutting Machine

- Download Product Catalog

Innovative R&D

With years of production experience and innovative R&D capabilities, Lienchy Laminated Metal continues to develop new functions or diversified coated steel...

Anti-Fingerprint Stainless Steel Coating Technology

Lienchy's anti-fingerprint color coated stainless steel products use high-tech coating to improve the fingerprint and corrosion resistance of stainless...

Process Equipment

Lienchy Laminated Metal is produced in a continuous production line to produce coated steel sheets, anti-fingerprint stainless steel, and pre-coated metals....