Stainless Scratch Silver Laminated Metal

Product No:H172

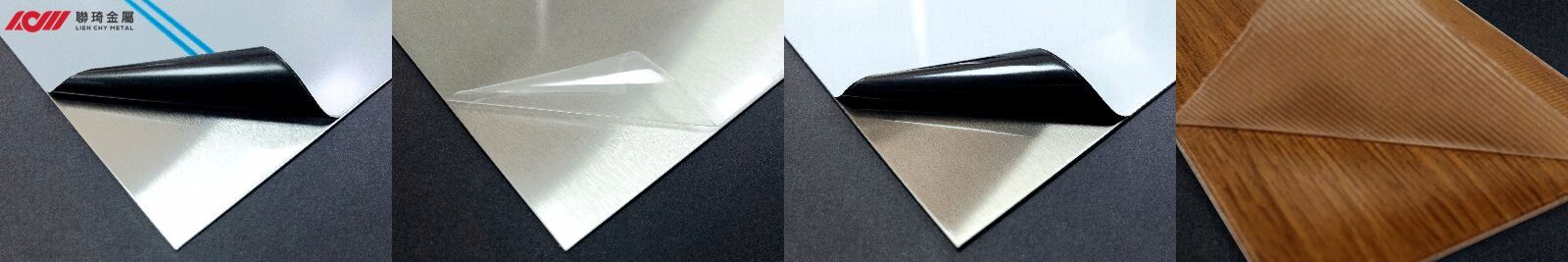

Stainless Scratch Silver metal laminate sheets, Stainless Scratch Silver pre-coated metal, Stainless Scratch Silver pvc clad metal, Stainless Scratch Silver vcm steel, Stainless Scratch Silver decorative metal laminate

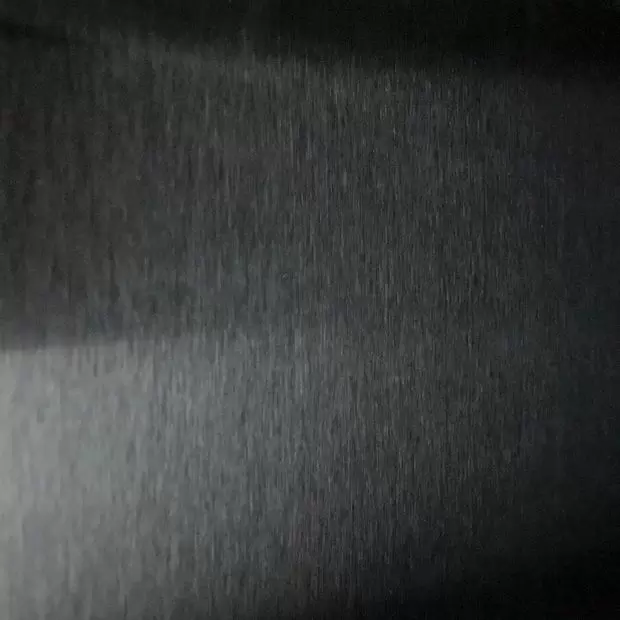

Stainless Scratch Silver (INOX LOOK) Laminated Metal boasts a smooth and radiant appearance, making it an excellent choice for home appliance exteriors.

Product Description

The Stainless Scratch Silver (INOX LOOK) laminated metal, mimicking stainless steel, features a mirror-like smooth surface with delicate hairline textures. It offers a brilliant metallic sheen without the need for complex processing.

Traditional stainless steel panels require various surface treatments and coatings to achieve an attractive appearance, but this can lead to color discrepancies and inconsistent textures. Laminated metal products use high-performance PET films bonded to metals such as EG, GI, GL, and AL. The continuous roll-to-roll production line ensures large areas of film adhere smoothly and uniformly, presenting a premium finish.

The mirror-like surface of the Stainless Scratch Silver laminated metal shines brightly under light, creating an elegant modern style. The brushed design provides fine and uniform textures, enhancing both the tactile and visual appeal.

Wide Applications

Stainless Scratch Silver (INOX LOOK) laminated metal not only boasts a unique mirror-like metallic sheen and hairline textures but also retains the durability and strength of metal. Whether for chassis of refrigerators, washing machines, dishwashers, or cabinets, doors, and wall panels in interior decoration, the Stainless Scratch Silver laminated metal meets consumers' demands for both appearance and quality.

Composition of the Stainless Scratch Silver (INOX LOOK) laminated metal plate

| (Layer) Structure | Thickness(㎛) | Type | Properties |

|---|---|---|---|

| (a) Coating | 2~3 | UV Coating | Anti-scratch,Gloss effect |

| (b) PET | 25~30 | - | - |

| (c) Hairline | 1 | Brushed | Hairline effect |

| (d)Metallization | 1 | Alulminum Metallization | Metallic effect |

| (e) Primer | 2~3 | - | Adhension with steel blank |

| Total Thickness | 31~38 | - | - |

Product Specification

- Product name: Stainless Scratch Silver Laminated Metal

- Product No. : H172

- Thickness of film:0.13mm

- Width of film:1300mm

Purchase Notes

The color of the product on the screen and the actual product may have a slight color difference due to the matching of product photography and your display device.

Please refer to the actual color of the product.

If you have requirement of sample, please send products inquiry to us.

Test Results

Test Report of Stainless Scratch Laminated Steel:

| Test Item | Test Method | Test Result |

|---|---|---|

| Hard Coating Adhesion |

| 3 Times,Without Peeling-off |

| Surface Hardness |

| Over HB |

| Bending Test | T-Bending 180° | No Film breaks 0T |

| Erichsen Test | Press in specimen | 6mm |

| Boiling Water resistance | boiling water for 2 hours | No Blisters/Rusting |

| Chemical Resistance | Acid Resistance:Immerse in 5%water solution of acetic Acid acid(CH3COOH) -Condition:20℃/24horus. | No Blisters/Rusting,No Change in gloss/color |

| Alkali Resistance:Immerse in 5%water solution of sodium hydroxide(NaOH) -Condition:20℃/24hours. | No Blisters/Rusting, No Change in gloss/color |

| Item | Name | Reference Standard | Test Result |

|---|---|---|---|

| Appearance | Gloss | JIS K 5600,ASTM D523 | Pass |

| Color difference | CIE1 976Lab,ASTM E313,ATM D2244 | See Sample | |

| Adhesive property(100 squares method) | JIS K 5600,ASTM D3359 | Pass | |

| Workability Test | Lamination property(Erichsen test) | JIS K 6744,JIS B 7729,LCM spec. | Pass |

| Bending property | JIS K 6 744,ASTM D4145 | Pass | |

| Low temperature processing property | JIS K 6744,ASTM D2671 | Pass | |

| Durability Test | Chemical resistance | JIS K 6744 | Pass |

| Stain resistance | JIS K 5600,CNS 423,CNS 11312,CNS 2984 | Pass | |

| Boiling water resistance | LCM spec.,JIS K 6744,ASTM D2485 | Pass | |

| Abrasion resistance | ASTM D4060 | Pass | |

| Salt spray test | JIS Z 2371,JIS K 8180,JIS Z8802 | Pass | |

| Cold and hot water circulation test | LCM spec.,JIS K 6744,ASTM D33359 | Pass |

If you want to get more information about post-processing,please referenceLaminated Metal Product

If you also want to know the anti-finger print stainless steel product,please referenceAnti-fingerprint Stainless Steel Product

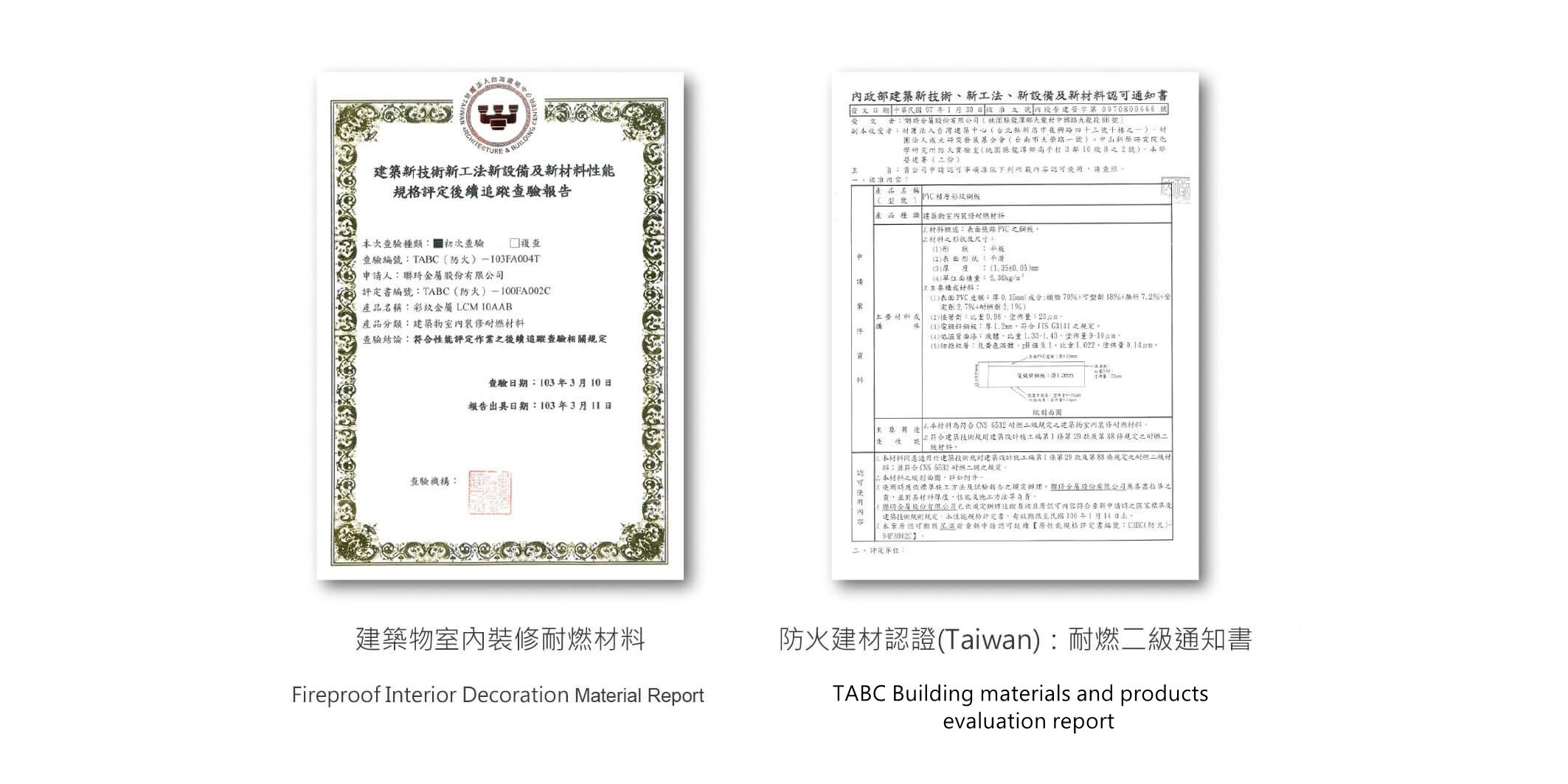

Fire Resistance Certificate

Complies with CNS 14705-1 test, class 2 fire resistance regulation.

| CNS 14705-1 Fire-Resistance Test Standard Applies constant heat power (50 kW/㎡) to a fixed-surface material | |||

|---|---|---|---|

| Fire Resistance Classification / Criteria | Level 1 | Level 2 | Level 3 |

| Heating Time (minutes) | 20 | 10 | 5 |

| Total Heat Release (MJ/㎡) | ≤ 8 | ≤ 8 | ≤ 8 |

| Duration above 200 kW/㎡ (seconds) | ≤ 10 | ≤ 10 | ≤ 10 |

| Presence of cracks or holes penetrating to the back that may compromise fire safety | None | None | None |

| Recommended Applications | Emergency escape routes, stairwells, hazardous material storage or high fire-risk areas | General indoor spaces, rooms with heating equipment, high-rise buildings, basements | General indoor areas |

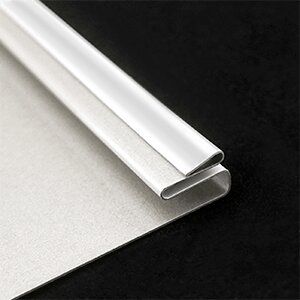

Steel Products Protective Film Option

We ship the product in coil or sheets, with customer assigned protective film or using our regular protective film (transparents/black-white) to protect the steel surface from scartch or any damage. Lien Chy Metal provides various service, for more information, please refer to Protective Film and Package

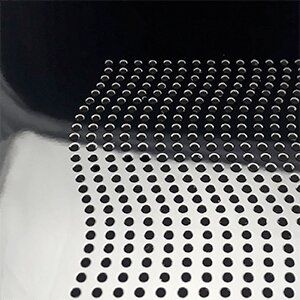

Processing

|  |  |  |  |

| T Bending | Deep Drawing | Punching | Emboss | V Bending |

|  |  |  |  |

| Roll Forming | Stamping | Printing | CNC Engraving | 180° Folding |

- Related Products

Light Gray Hairline Laminated Metal

Product No:A153

The Light Gray Hairline Laminated Metal features a surface adorned with delicate, three-dimensional...

DetailsHairline Metallic Laminated Metal

Product No:A135

The surface of the Hairline Metallic laminated metal is filled with intricate 3D hairline finish(HL)...

Details- Product Catalog Download

Laminated Metal Products | Metal Surface Processing | Lienchy Metal

Based in Taiwan since 1992, LIENCHY LAMINATED METAL CO., LTD. has been a laminated metal products manufacturer. Their main laminated metal products include, Stainless Scratch Silver Laminated Metal, pre-coated steel sheet, PPGI, PPGL, PPAL, pre-painted steel sheet, pre-finished steel sheet, anti-fingerprint stainless steel, pvc laminated metal sheet, pvc coated metal sheet, pvdf laminated metal sheet, titanium coated stainless steel sheet, pre-painted metal sheet, coil steel sheet and titanium coated stainless steel sheet, which are produced with a 350M roll-to-roll production line and 50,000 tons annual production capacity.

Lienchy Metal is capable of manufacturing ISO certified 1.6mm-thick laminated steel sheets and meet SGS, RoHS and GREENGUARD standards. We are long-term partner of EU and US home appliance brands and Japanese elevator factories, our products have also been exported to all over the world, from Taiwan, Japan, South Korea, China, ASEAN countries, the United Arab Emirates, Russia, Europe and North America.

Lienchy Metal has been offering customers high-quality laminated metal and anti-fingerprint stainless steel products, both with advanced technology and 30 years of experience, Lienchy Metal ensures each customer's demands are met.