Titanium Coated Embossed Stainless Steel Panels

Elegant, Durable, and Versatile Interior Decorative Material

DSP titanium coated embossed stainless steel panels are a unique combination of high-grade stainless steel and luxurious titanium colors, enhanced by cutting-edge PVD (Physical Vapor Deposition) technology.

This premium decorative material not only adds elegance to any space but also offers exceptional durability and versatility, making it ideal for walls, ceilings, kitchen furniture, and more, perfectly blending modern craftsmanship with eco-friendly principles.

Feature of DSP Titanium Embossed Stainless Steel Panels

The DSP titanium coated embossed stainless steel panels from Lienchy Metal utilize advanced PVD technology, depositing titanium ions onto the stainless steel surface in a high-temperature vacuum environment. This process creates a highly durable titanium coating, significantly enhancing the material's hardness, wear resistance, and corrosion resistance. This coating technique is not only widely used in interior design but also in high-tech industries such as automotive and electronics manufacturing.

Product Features

- Luxurious Finish, Exceptional Craftsmanship: Using cutting-edge PVD titanium ion coating technology, the DSP titanium coated embossed stainless steel panels showcase exquisite metallic luster, with various design options, from classic embossing to glossy mirror and matte finishes, catering to diverse design preferences.

- Eco-friendly Process, Health and Safety: The production process is certified by the U.S. GREENGUARD for being non-toxic. It is suitable for environments requiring high levels of cleanliness, such as schools and hospitals, ensuring the health and safety of you and your family.

- Versatile Applications, Flexible Design: These panels can be applied to various substrates, such as galvanized steel or wood, enhancing design flexibility. Whether for walls, ceilings, or kitchen surfaces, this material adds a touch of luxury to any interior design.

- Exceptional Durability, Long-lasting Appeal: Titanium coated embossed stainless steel panels undergo rigorous testing for wear, corrosion, and impact resistance. The PVD titanium coating is ten times harder than regular stainless steel, effectively preventing scratches and wear for long-term use.

- Fingerprint Resistant, Easy to Clean: Treated with a nano-ceramic anti-fingerprint coating (NCC), the surface remains smooth and free of fingerprints or stains. A simple wipe is enough to maintain its clean and shiny appearance, ideal for public spaces.

Durability Result of DSP Titanium Stainless Steel Panel

- Film Hardness: The film hardness of DSP titanium coated panels is 10 times higher than that of regular stainless steel.

- Adhesion Strength: After scratch and tape peeling tests, no film detachment was observed on the surface.

- Impact Resistance: After a 1kg steel ball was dropped from 50 cm using a DuPont impact tester, the DSP titanium coated panel surface remained undamaged.

- Wear Resistance: Under 500g of pressure, after 200 cycles of rubbing, the film surface remained intact without any damage or peeling.

- Sweat Corrosion Resistance: After immersing the panels in artificial sweat (PH4.5) for 8 hours, no signs of corrosion or discoloration were observed.

- Moisture and Rust Resistance: After being placed in a 50°C, 98% humidity environment for 500 hours, no rust or discoloration was observed.

Recommended Interior Applications

Titanium coated embossed stainless steel panels are ideal for various interior spaces, from luxurious residential interiors to commercial spaces, restaurants, schools, hospitals, and other public areas with high cleanliness standards. Its durability and ease of maintenance make it an excellent choice for environments requiring frequent cleaning while enhancing the overall aesthetic and quality of any space.

Product specification

| Product Name | TI-COLOR | INOXTEEL | |||

|---|---|---|---|---|---|

| Color | |||||

| Product Photo |  |  |  |  |  |

| Finishing | |||||

| Type | Sheet | Sheet | |||

| Blank Thickness | 1.2/1.5t | 1.5t | 1.5t | 1.2t | 1.2t |

| Width | 1219mm | 600mm | |||

| Length | 2438mm | 2438mm | |||

| In Stock | v | v | x | v | v |

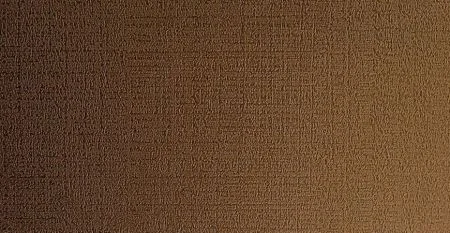

| Product Name | VERNOX | |||

|---|---|---|---|---|

| Color | Bronze | |||

| Product Photo |  |  |  |  |

| Finishing | ||||

| Type | Sheet | |||

| Blank Thickness | 1.26t | |||

| width | 600mm | |||

| Length | 2438mm | |||

| In Stock | v | |||

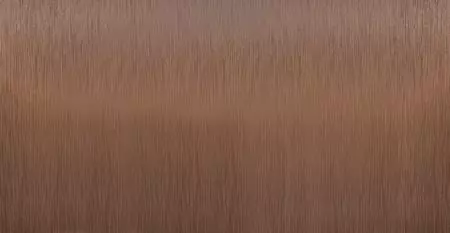

| Product Name | VERNOX | |||

|---|---|---|---|---|

| Color | Black | |||

| Product Photo |  |  |  |  |

| Finishing | ||||

| Type | Sheet | |||

| Blank Thickness | 1.26t | |||

| Width | 600mm | |||

| Length | 2438mm | |||

| In Stock | v | |||

The color of the product on the screen and the actual product may have a slight color difference due to the matching of product photography and your display device.

Please refer to the actual color of the product.

If you have requirement of sample, please send products inquiry to us.

Other similar products

If you need other copper/ black or other metal sheets with similar appearance, you can refer to the following products

Package Method

We ship the product in coil or sheets, with customer assigned service, Lien Chy Metal will meet your expectation, like we always do, for more information, please refer to Protective Film and Package

Brass Frieze Texture Laminated Metal

Product No:C126

The color of brass will show different changes due to the exposure of light, sometimes it is a warm...

DetailsBronze Embossed Texture Laminated Metal

Product No:C140

The refined bronze sheen, combined with intricate embossed patterns, creates an atmosphere...

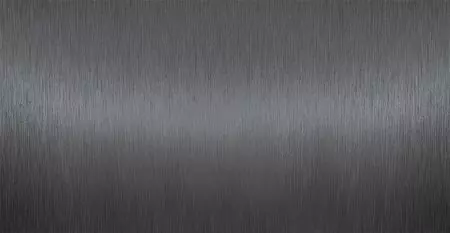

DetailsHairline Metallic Laminated Metal

Product No:A135

The surface of the Hairline Metallic laminated metal is filled with intricate 3D hairline finish(HL)...

DetailsLight Gray Hairline Laminated Metal

Product No:A153

The Light Gray Hairline Laminated Metal features a surface adorned with delicate, three-dimensional...

DetailsNano Ceramic Anti-fingerprint Stainless Steel

Product No:TA082

Nano Ceramic Anti-fingerprint Stainless Steel-TA082

DetailsTrendy Black Anti-fingerprint Stainless Steel

Product No:TA078

The pure metal texture and pattern of stainless steel can be matched with different decoration...

DetailsTransparent Matte Finish Anti-fingerprint Stainless Steel

Product No:TA052

Transparent Matte Finish Anti-fingerprint Stainless Steel-TA052

DetailsRose Gold Anti-fingerprint Stainless Steel

Product No:TA058

The pure metal texture and pattern of stainless steel can be matched with different decoration...

DetailsTungsten Black Anti-fingerprint Stainless Steel

Product No:TA059

The pure metal texture and pattern of stainless steel can be matched with different decoration...

DetailsChampagne Gold Anti-fingerprint Stainless Steel

Product No:TA060

The pure metal texture and pattern of stainless steel can be matched with different decoration...

DetailsGlossy Finish Anti-fingerprint Stainless Steel

Product No:TA061

Glossy Finish Anti-fingerprint Stainless Steel-TA061

DetailsAnti-Corrosion Steel Sheets Manufacturer | Lienchy Laminated Metal

Based in Taiwan since 1992, LIENCHY LAMINATED METAL CO., LTD. has been a laminated metal products manufacturer. Their main laminated metal products include, Titanium Coated Embossed Stainless Steel Panels, pre-coated steel sheet, PPGI, PPGL, PPAL, pre-painted steel sheet, pre-finished steel sheet, anti-fingerprint stainless steel, pvc laminated metal sheet, pvc coated metal sheet, pvdf laminated metal sheet, titanium coated stainless steel sheet, pre-painted metal sheet, coil steel sheet and titanium coated stainless steel sheet, which are produced with a 350M roll-to-roll production line and 50,000 tons annual production capacity.

Lienchy Metal is capable of manufacturing ISO certified 1.6mm-thick laminated steel sheets and meet SGS, RoHS and GREENGUARD standards. We are long-term partner of EU and US home appliance brands and Japanese elevator factories, our products have also been exported to all over the world, from Taiwan, Japan, South Korea, China, ASEAN countries, the United Arab Emirates, Russia, Europe and North America.

Lienchy Metal has been offering customers high-quality laminated metal and anti-fingerprint stainless steel products, both with advanced technology and 30 years of experience, Lienchy Metal ensures each customer's demands are met.